Top AI Robotics Tools for Manufacturing in 2025

December 5, 2024

The manufacturing industry has undergone a significant transformation with the advent of AI and robotics. AI Robotics Tools have emerged as a powerful solution to automate various tasks, improve efficiency, and enhance product quality. By combining the precision of robotics with the intelligence of AI, these tools are revolutionizing manufacturing processes. To effectively reach target audiences and promote the benefits of these innovative technologies, businesses can leverage mobile marketing campaigns to engage potential customers and drive sales.

AI Robotics Tools combine robotic systems and artificial intelligence algorithms that enable machines to perform tasks autonomously. These tools have sensors, actuators, and advanced software to perceive their environment, make decisions, and execute actions.

AI Robotics Tools are composed of several key components that work together to enable intelligent and autonomous behavior:

This includes the robot’s physical structure, including its arms, joints, and end-effectors.

These devices allow the robot to perceive its environment, including cameras, lidar, and force sensors.

These components, such as motors and servos, enable the robot to move and interact with its environment.

AI algorithms enable robots to learn from data and improve their performance over time.

This technology allows robots to interpret visual information from cameras and other sensors.

NLP enables robots to understand and respond to human language.

Analyzing visual data to identify objects and their locations.

We recognize and classify objects in the robot’s environment.

Tracking the movement of objects and people.

Enabling communication between the robot and other devices and systems.

We are sharing data and information with other devices to improve decision-making.

Monitoring and controlling robots remotely.

Precise and efficient assembly of products.

Reduced labor costs and increased productivity.

Automated inspection and quality assurance.

Identification of defects and inconsistencies.

Automated material handling and transportation.

Optimized inventory management and order fulfillment.

Real-time monitoring of equipment health.

Predictive maintenance to prevent breakdowns.

AI Robotics has the potential to revolutionize the manufacturing industry, offering numerous benefits:

Robots can automate repetitive and time-consuming tasks, freeing human workers for more complex and strategic work.

Robots can work around the clock, increasing overall productivity.

Robots can perform tasks with high precision and accuracy, reducing human error.

AI-powered vision systems can identify defects and inconsistencies in products.

Robots can perform tasks in hazardous environments, such as handling toxic chemicals or working in extreme temperatures.

Robots can reduce the risk of workplace injuries by automating repetitive and dangerous tasks.

AI-powered robots can quickly adapt to changes in production requirements.

Robots can be programmed to perform various tasks, making them versatile and adaptable.

AI-powered robots can collect and analyze data to optimize production processes.

By monitoring equipment health, AI can predict and prevent breakdowns.

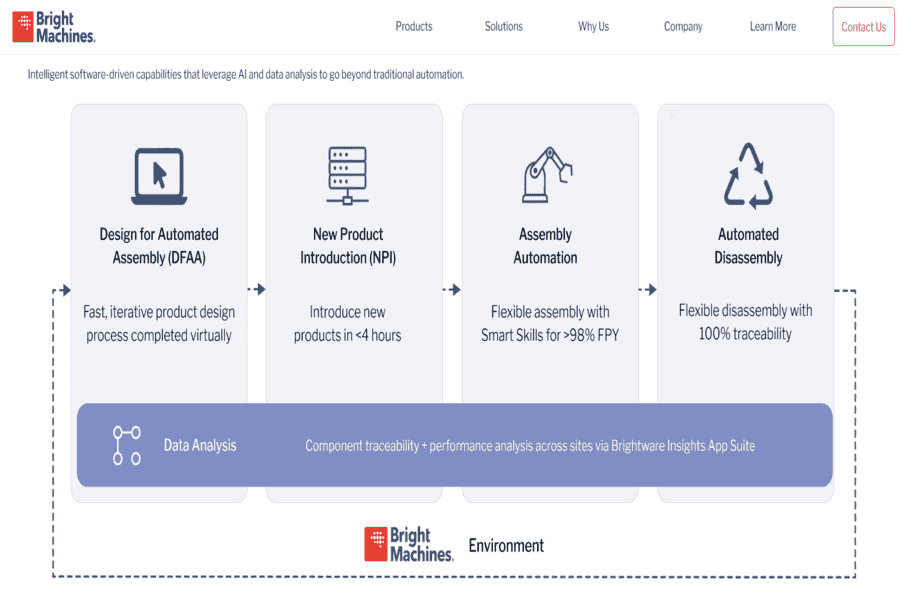

Combines AI and robotics to provide automated microfactories for assembly and inspection.

High customization, scalable automation, and real-time analytics.

It is an expensive initial setup for small manufacturers.

Custom pricing based on solutions required.

Develops collaborative robots powered by AI to optimize manufacturing tasks.

Easy to program, safe for human interaction, and affordable.

Limited payload capacity.

Custom pricing based on robot models and needs.

AI-driven robotics software automates tasks such as sorting and picking in warehouses and manufacturing.

Excellent in dynamic environments and self-learning capabilities.

Limited hardware options.

Custom pricing based on the project.

Offers collaborative robots (cobots) that can easily automate manufacturing tasks.

User-friendly, wide application range, reliable support.

Requires external software for complex tasks.

Starts at $35,000 per robot.

AI-integrated industrial robotics for applications like welding, assembly, and material handling.

Highly reliable, wide range of robot models, AI enhancements for precision.

Complex programming for non-specialists.

Custom pricing based on robot type and applications.

Provides AI-enhanced industrial robots for various manufacturing applications, including welding, painting, and assembly.

High precision, a wide range of robot models, and extensive global support.

Expensive for small-scale operations.

Custom pricing based on robot and application.

Develops advanced robots with AI for inspection, warehouse automation, and manufacturing support tasks.

Exceptional mobility, advanced AI for automation, and scalable solutions.

High-cost, niche applications.

Custom pricing: robot units like “Stretch” and “Spot” have specific costs starting at $75,000.

Offers AI-powered robotics for warehouse and manufacturing operations, specializing in material handling and sorting.

We optimized for efficiency, excellent scalability, and advanced machine learning for dynamic tasks.

Primarily focuses on logistics rather than heavy manufacturing.

Custom pricing based on deployment size.

A leader in robotics and automation, KUKA integrates AI into their robots for various manufacturing tasks, including assembly and inspection.

Flexible, industry-specific solutions with a strong global presence.

It is complex for beginners and requires advanced integration support.

Custom pricing based on robot models and project scope.

Specializes in AI-guided robotics for material recycling and manufacturing processes like sorting and picking.

Eco-friendly focus, reduces manual labor, cost-effective in waste management.

Limited to specific industries.

Custom pricing based on deployment size and requirements.

While AI Robotics offers significant benefits, there are several challenges and limitations to consider:

The initial investment in robotic hardware, software, and infrastructure can be substantial.

Ongoing maintenance and repair costs can be significant.

Developing and integrating AI-powered robots requires specialized skills and expertise.

Troubleshooting complex robotic systems can be time-consuming and challenging.

Automation of routine tasks may lead to job losses in certain sectors.

The transition to automation may require significant workforce retraining.

Ensuring the safety of human workers working alongside robots is crucial.

The potential for malfunction or unexpected behavior can pose safety risks.

The impact of automation on employment and the economy must be carefully considered.

They are ensuring that AI-powered robots are unbiased and fair in their decision-making.

The future of AI robotics in manufacturing is promising, with several exciting trends emerging:

Cobots are designed to work safely alongside humans, enhancing productivity and flexibility.

Cobots can take on repetitive or dangerous tasks, freeing human workers for more complex and creative work.

AMRs can navigate dynamic environments and transport materials autonomously.

AMRs can optimize warehouse operations by automating picking, packing, and shipping tasks.

Improved computer vision algorithms enable robots to perceive and understand their environment more accurately.

Robots can quickly identify and track objects in real time, enabling faster and more precise actions.

Processing data locally on the robot reduces latency and improves responsiveness.

Edge computing enables robots to make decisions independently, even with limited connectivity.

AGI could enable robots to exhibit human-level intelligence and adaptability.

AGI-powered robots could tackle complex tasks that require creativity and problem-solving skills.

AI Robotics Tools are transforming the manufacturing industry by improving efficiency, quality, and safety. As technology advances, we can expect to see even more innovative applications of AI robotics in the future. By addressing the challenges and embracing the opportunities, manufacturers can reap the benefits of this powerful technology.