Best AI-Powered Warehouse Automation Tools in 2025

November 29, 2024

Warehouse automation integrates technology into warehouse operations to increase efficiency, accuracy, and productivity. Businesses can reduce labor costs, minimize errors, and improve performance by automating picking, packing, and shipping tasks. This article explores the key aspects of warehouse automation, including its benefits, challenges, and future trends.

It’s important to use project planning software to effectively manage warehouse automation projects. This software can help you create detailed project plans, track progress, and identify potential risks, ensuring your automation initiatives succeed.

Warehouse automation integrates technology into warehouse operations to increase efficiency, accuracy, and productivity. Businesses can streamline their supply chain, reduce labor costs, and improve customer satisfaction by automating various tasks.

These systems use robotic arms to store and retrieve goods from high-density storage racks. They optimize storage space, improve order-picking accuracy, and increase throughput.

Conveyor systems transport goods efficiently within the warehouse, reducing manual handling and improving workflow. They can be used to move pallets, boxes, and individual items.

AMRs are mobile robots that can navigate the warehouse autonomously, transporting goods to different locations. They can adapt to changing warehouse layouts and avoid obstacles, making them highly flexible and efficient.

WMS software provides a centralized platform for managing warehouse operations, including inventory control, order fulfillment, and labor management. It helps optimize workflows, reduce errors, and improve overall efficiency.

Robots can perform various tasks, such as picking, packing, palletizing, and sorting. Depending on the specific application, they can work autonomously alongside human workers.

Implementing warehouse automation is a complex process that requires careful planning and execution. Here are the key steps involved:

Analyze current warehouse operations to identify bottlenecks, inefficiencies, and areas where automation can add value.

Set clear objectives for the automation project, such as increasing productivity, reducing costs, or improving accuracy.

Assess the current warehouse layout, equipment, and software to determine compatibility with automation technologies.

Select automation technologies that align with your specific needs and budget. Consider factors like scalability, flexibility, and integration capabilities.

Research and compare different vendors to find the best fit for your business.

Choose technologies that can adapt to future growth and changes in your business.

Ensure seamless integration between the automation system and your warehouse management system (WMS) and other software.

Create clear and efficient workflows to optimize the use of automation technology.

Thoroughly test the integrated system to identify and address issues before full deployment.

Provide comprehensive training to employees on using the new technology and operating the automated systems.

Create detailed documentation and guidelines to ensure consistent operations.

Implement the automation system in stages to minimize disruption and allow for gradual adjustments.

Track key performance indicators (KPIs) to measure the impact of automation.

Continuously analyze data to identify opportunities for optimization.

Be prepared to adjust the automation system as your business evolves.

Warehouse automation offers a multitude of benefits for businesses:

Automation can significantly reduce labor costs by automating repetitive and time-consuming tasks.

Automated systems can operate 24/7, increasing overall productivity and throughput.

Automated systems minimize errors in picking, packing, and shipping processes.

Automated systems provide accurate and up-to-date inventory data, reducing stockouts and overstocks.

Automation eliminates the need for manual handling of heavy loads, reducing the risk of injuries.

Automated systems can create a safer and more comfortable work environment for employees.

Automated storage and retrieval systems maximize storage capacity.

Real-time tracking of inventory levels reduces stockouts and overstocks.

Automated systems can quickly process and fulfill orders.

Reduced processing time leads to faster delivery times.

An AI-powered robotic system for automating inventory management and warehouse operations.

High efficiency, modular design, seamless scalability.

Requires significant initial investment.

Custom pricing upon request.

Contact Information:

AI-driven robotic systems and software for warehouse automation.

AI-powered real-time decision-making integrates with WMS/ERP.

Custom implementation can be time-consuming.

Available upon request.

Autonomous mobile robots (AMRs) are designed to improve warehouse productivity.

Easy to deploy, high ROI, minimal disruption to existing operations.

Best suited for specific warehouse sizes.

Subscription-based model.

Offers AMRs and cloud robotics solutions for warehouses.

Real-time cloud integration of a wide range of robot models.

Heavy reliance on cloud infrastructure.

Available on request.

AI-powered material handling and logistics automation solutions.

Flexibility, AI optimization, and integration with existing systems.

Custom setups may require technical expertise.

Tailored pricing based on needs.

Advanced AI and robotic solutions for warehouse and supply chain automation.

Comprehensive solutions and a strong global support network.

Implementation can be complex for smaller businesses.

Custom quotes are available upon consultation.

AI-driven robotics and fulfillment solutions for e-commerce and retail warehouses.

High adaptability to various industries and strong AI analytics.

Primarily focused on larger operations.

Tailored packages are available on request.

AI-driven AMRs and intelligent software solutions for warehouse automation.

Wide range of robots, flexible solutions, and quick deployment.

Limited availability in certain regions.

Custom pricing depending on project requirements.

AI-enabled robotic and software solutions for warehouse and logistics automation.

Robust systems, strong integration capabilities, proven reliability.

Higher initial costs for advanced solutions.

Available upon consultation.

AI-powered supply chain and warehouse management software solutions.

Excellent AI-based forecasting, strong analytics, scalable.

I was primarily focused on software rather than robotics.

Subscription-based pricing upon request.

Provides AI-driven warehouse solutions, including robotics and data-driven analytics.

Excellent inventory tracking, diverse product offerings, and strong global presence.

Some solutions require extensive system integration.

Customized pricing based on solutions chosen.

High-density robotic storage and retrieval systems powered by AI.

Space-saving, energy-efficient, reliable automation.

Focuses on storage rather than holistic warehouse automation.

Quote available upon consultation.

AI-powered fulfillment automation using autonomous mobile robots and optimization software.

Scalable, subscription-based pricing, fast deployment.

Best for small to medium-sized warehouses.

Pay-as-you-go subscription model.

AI-powered robots for handling repetitive and labor-intensive tasks in warehouses.

Advanced robotics, innovative technology, versatile use cases.

High upfront costs for advanced systems.

Custom pricing based on robot and deployment.

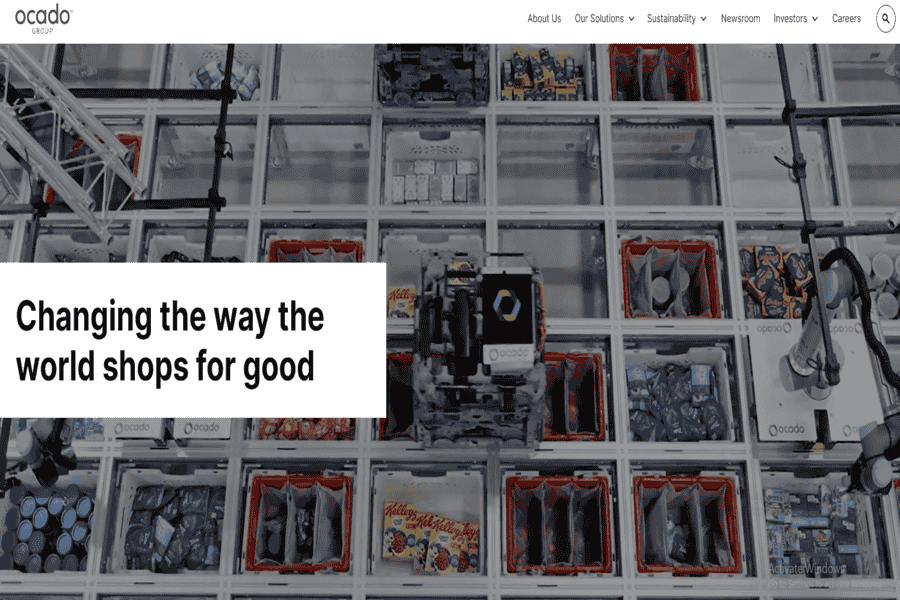

AI-powered end-to-end automation for grocery warehouses, including robotic picking.

Tailored for grocery and retail, it is highly efficient.

Limited to specific industries.

Partnership and licensing-based pricing.

Provides AI-driven warehouse robotics solutions, including sorting, picking, and palletizing systems.

Trusted brand, reliable systems, diverse product range.

Higher costs for customization.

Tailored pricing is available upon request.

AI-powered robotic picking systems designed for e-commerce and logistics warehouses.

High precision, integrates easily with existing workflows.

Limited to picking and sorting tasks.

Custom pricing is available upon consultation.

Offers AI-driven collaborative mobile robots (Chuck) to enhance warehouse picking efficiency.

Easy to implement, reduces the walking time for workers.

Best for medium-sized operations.

Subscription-based pricing is available upon inquiry.

Autonomous guided vehicles (AGVs) and autonomous mobile robots (AMRs) for warehouse transportation.

Versatile solutions, high payload capacity, reliable navigation systems.

Requires a structured environment for optimal use.

Custom pricing based on requirements.

AI-driven robots for intelligent order picking and material handling in warehouses.

Advanced AI has high flexibility for various applications.

Limited availability in certain regions.

Custom pricing is available on request.

While warehouse automation offers numerous benefits, it also presents several challenges:

Implementing warehouse automation systems can be a significant investment for smaller businesses. The cost of purchasing and installing automated equipment, software, and infrastructure can be substantial.

Integrating various automation technologies and ensuring seamless operation can be complex. It requires specialized expertise and technical skills to design, implement, and maintain these systems.

As automation increases, warehouse workers are concerned about job displacement. However, it’s important to note that automation often creates new job opportunities, such as system operators and maintenance technicians.

Employees may resist change and require training and support to adapt to new technologies and work processes. It’s crucial to involve employees in the automation process and address their concerns to minimize resistance.

The future of warehouse automation is promising, with several emerging trends shaping the industry:

AI and ML algorithms can analyze historical data to predict future demand, optimize inventory levels, and improve forecasting accuracy.

AI can optimize the routes of autonomous robots and workers to minimize travel time and maximize efficiency.

AI-powered vision systems can inspect products for defects and quality issues.

AMRs will become more autonomous and capable of navigating complex warehouse environments without human intervention.

AMRs will work collaboratively with human workers, sharing tasks and improving productivity.

AMRs will be equipped with advanced sensors and perception systems to navigate dynamic environments and avoid obstacles.

IoT devices can track the location and status of inventory items in real-time, improving inventory accuracy and reducing stockouts.

IoT sensors can monitor the condition of warehouse equipment and predict potential failures, minimizing downtime.

IoT devices can monitor temperature, humidity, and other environmental factors to ensure optimal storage conditions.

Robots will become more sophisticated and capable of performing complex tasks such as picking fragile items and handling diverse product types.

Cobots will work alongside human workers, improving efficiency and safety.

AGVs will continue to be used for material handling and transportation within warehouses.

As technology advances, AI-powered warehouse automation tools are revolutionizing how businesses operate. By streamlining processes, improving accuracy, and enhancing efficiency, these tools are driving significant improvements in warehouse productivity and profitability. As AI and robotics continue to evolve, we can expect to see even more innovative solutions that will shape the future of warehouse automation.